Schumacher Tri-Y headers are great for BB A-body engine swaps because they're designed with clearance in mind for steering components and starter access. They tend not to hang as low as a full length header.

The trade-off is a moderate tube diameter and a slight HP loss compared to their traditional counterparts. But on the street, I'd wager the difference would be unnoticeable. The benefits just outweigh the hassle often associated with other headers. Nevertheless, a step up from these would be TTI's.

That being said, I'll admit these are not the best choice for a blown engine. You want exhaust gasses to exit as quickly and effortlessly as possible for maximum power. Alas, a new set of large diameter, full length tube headers weren't in the budget. I'll trade a few ponies for dollars saved and fewer headaches.

The trade-off is a moderate tube diameter and a slight HP loss compared to their traditional counterparts. But on the street, I'd wager the difference would be unnoticeable. The benefits just outweigh the hassle often associated with other headers. Nevertheless, a step up from these would be TTI's.

That being said, I'll admit these are not the best choice for a blown engine. You want exhaust gasses to exit as quickly and effortlessly as possible for maximum power. Alas, a new set of large diameter, full length tube headers weren't in the budget. I'll trade a few ponies for dollars saved and fewer headaches.

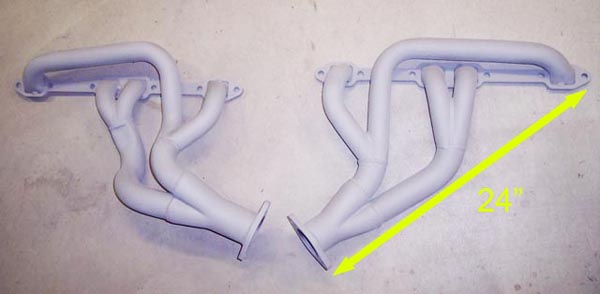

Original headers with DIYcoating from Techline called "Colorgard Stainless"

The Schumacher headers had nice beefy flanges to begin with but when I pulled them off I found slight leaks around the center exhaust ports.

Mike at Schumacher told me they've been improved since I bought them years ago and even offered to replace them. Instead, I decided to recoat them myself and install them with Remflex Gaskets which, I'd say, rank right up there with sliced bread on the list of great things.

The original DIY coating I applied was from Techline and I'd give it a very conservative "OK" as thermal coatings go.

This time I decided to try Cerakote Chromex (2 - 4oz. bottles) which I purchased through Caswell Plating.

Mike at Schumacher told me they've been improved since I bought them years ago and even offered to replace them. Instead, I decided to recoat them myself and install them with Remflex Gaskets which, I'd say, rank right up there with sliced bread on the list of great things.

The original DIY coating I applied was from Techline and I'd give it a very conservative "OK" as thermal coatings go.

This time I decided to try Cerakote Chromex (2 - 4oz. bottles) which I purchased through Caswell Plating.

I have a friend who owns a powder coat business. Despite the fact that they don't specialize in high temp ceramic finishes, he agreed to help.

The first step was to media blast the old coating off to expose fresh metal and then bake them to burn off any remaining contaminants..

Then, I used a spray gun to apply the Chromex, as is, right out of the bottle. It went on a little lumpy as it doesn't atomize real fine. The product appears to be water based.

After 20 min. of air drying they went in the oven for 20 min. at 175 degrees. This helped evaporate excess solvents. After that, the oven was cranked up to 500 degrees for 60 min for a full cure.

They came out looking the way they did going in - a matte gray finish and can be burnished with steel wool before polishing.

The first step was to media blast the old coating off to expose fresh metal and then bake them to burn off any remaining contaminants..

Then, I used a spray gun to apply the Chromex, as is, right out of the bottle. It went on a little lumpy as it doesn't atomize real fine. The product appears to be water based.

After 20 min. of air drying they went in the oven for 20 min. at 175 degrees. This helped evaporate excess solvents. After that, the oven was cranked up to 500 degrees for 60 min for a full cure.

They came out looking the way they did going in - a matte gray finish and can be burnished with steel wool before polishing.

We don't have the luxury of a vibratory tumbler anywhere around here so any polishing would have to be done by hand.

The cured coating is pretty tough so I started by wet sanding the finish to remove excess orange peel and dry spray. This worked okay but proved very slow so I switched to using a DA sander with 400 grit where possible. This worked really well.

After that I spent time with a buffing wheel and compound on a bench grinder to bring out the shine. Once installed, you'll never see the little nooks and crannies missed by the buffer. It made a huge difference and is far and away superior to the Techline product.

Of course, the simplest thing to do if you have several hundred dollars is just send your headers out to a place like Jet-Hot to be coated.

The cured coating is pretty tough so I started by wet sanding the finish to remove excess orange peel and dry spray. This worked okay but proved very slow so I switched to using a DA sander with 400 grit where possible. This worked really well.

After that I spent time with a buffing wheel and compound on a bench grinder to bring out the shine. Once installed, you'll never see the little nooks and crannies missed by the buffer. It made a huge difference and is far and away superior to the Techline product.

Of course, the simplest thing to do if you have several hundred dollars is just send your headers out to a place like Jet-Hot to be coated.

While on the subject of exhaust we later decided to try a muffler swap to see what a more aggressive exhaust note would be like.

Staying within the Pypes Performance family, I ordered a pair of Violator mufflers form Summit. The design is very similar to the Race Pro with a straight pipe design inside.

The difference is, the perforations are larger and are stamped so that they protrude into the air stream. The case is also empty - no wrap or packing inside.

It is a directional design, meaning one end is marked as the inlet.

Staying within the Pypes Performance family, I ordered a pair of Violator mufflers form Summit. The design is very similar to the Race Pro with a straight pipe design inside.

The difference is, the perforations are larger and are stamped so that they protrude into the air stream. The case is also empty - no wrap or packing inside.

It is a directional design, meaning one end is marked as the inlet.

By turning it around and installing it "backwards" you can change the tone of the exhaust. Others have done this and I too found the sound more pleasing. It's definitely louder and approaches the sound of open exhaust.

We did a quick comparison video of the two different mufflers at idle. I ultimately returned to the Race Pro which is more pleasing to me.

To see a longer version of the Race Pro click here.

We did a quick comparison video of the two different mufflers at idle. I ultimately returned to the Race Pro which is more pleasing to me.

To see a longer version of the Race Pro click here.

For best results set playback quality to 360p or higher

|

|

|

|

|

|

|

|

|

© 2013 JP Herrick Enterprises - All Rights Reserved

Site updated: January 2014