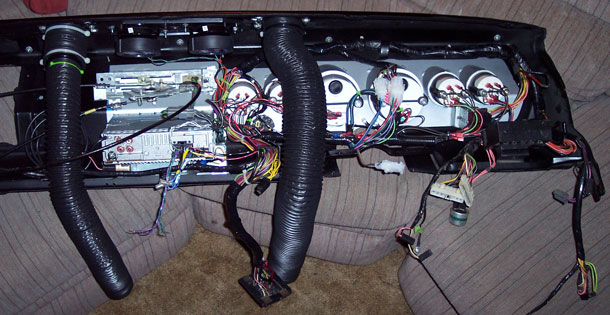

The original dash assembly..... What can I say except.... Yikes?!

(Below) A Rocky Mountain Dash (company later went out of business) right out of the box. Wow! Heavy, heavy gauge aluminum, precision cut and welded. They're available in a number of gauge configurations or you can design your own. They're built to order. This is one fine piece and I haven't decided yet how I'm going to finish it. The "texture" you see are the sanding marks made to clean up tool marks during manufacturing. They'll powdercoat too if you wish. Can't wait to see some Autometer gauges in there.

UPDATE: Rocky Mountain Dashes has returned to the marketplace as Peak Dashes.

UPDATE: Rocky Mountain Dashes has returned to the marketplace as Peak Dashes.

Here, I've started mockup of the Rocky Mountain Dash inserts. After it's stripped of everything, the dash frame is way too flimsy and awkward to do much of this on the workbench. In my case, trimming of the frame is required for the main insert to fit correctly. Unless you get the original "cluster only" insert this is normal - and not for the faint of heart if you're afraid to cut up your car. My gauge layout required that I remove material in the area of the heater and radio controls. This made the frame even flimsier so I mounted it back in the car for mockup. Some creative bracketry will be needed to mount the original heater controls back into the new bezel. The radio cutout is for a standard DIN chassis stereo system. And, I'll be reusing the original headlight and wiper switches in the holes provided.

The Rocky Mountain Dash, though a nice piece, like many custom parts, is not a "slam dunk" installation. In my case there was some trimming of the dash frame and some tweaking to get the glove box door to fit and look right. The other issue was installation of the heater control.

I had to fabricate a couple of brackets to mount it to the RMD bezel in the best position.

Looks good once it's all in place though...

Above, the main inserts got a coat of Sikkens metallic silver base with semi-flat clear..

The insert was then loaded with a compliment of AutoMeter Sport Comp II gauges. With their backlit LED technology they look killer in the dark - just like modern cars. Overall, the new dash is a stark contrast to the original cluster and wood-grain design.

Painless Performance makes a universal wiring harness for aftermarket gauges. Changing the plug on the factory harness will make this nearly a plug-in deal. I could have done all the wiring from scratch but this saved a lot of time and made for clean results.

The other portion of the dash insert - a glove box door cover - finishes it off. I used acorn nuts and small machine screws to mate the two. RMD sends regular sheet metal screws. In the picture, the knob has not been installed yet.

With the metal dash frame refinished in black, the only remaining piece is the pad itself. A few years ago I bought a dash cap which is a hard molded plastic shell or skin that glues over the original pad. It fits pretty well and looks okay but there were a couple of spots that didn't cover to my satisfaction. I also tried a reproduction pad from Year One. It was injection molded urethane. The look and feel was about right but it wouldn't quite bolt to the frame correctly and there were some other issues I wasn't too thrilled about. So, I sent it back.

I sent the original pad to Dashboard Restorations USA here in Washington state. They use a process like Just Dashes in CA, are comparably priced, and turned in around in about 6 weeks.

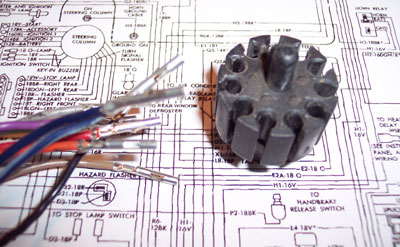

In January 2008, with painting of the body complete, it was time for reassembly. There were some things to finish up on the dash so I pulled out the dash wiring harness for some changes.

First was to change the old cluster plug to the new “Painless” one. It was simply a matter of removing the old terminals and replacing them with the ones supplied with the universal gauge harness. They just crimp on.

Then, it was simply a matter of matching the original harness wires to the appropriate wire on the female half of the cluster harness plug. It’s very easy to do with the new gauge cluster sitting right there.

New wiring for the electric speedo and tach can be run separately. In a couple of cases I either ran a new wire, taping it to the original harness, or reused an existing circuit wire for a circuit no longer in use.

For example, I did away with the brake warning lamp. I don’t have an indicator on the Rocky Mountain Dash and don’t feel I need one. The light is designed to come on after a brake system “failure” anyway - which is kind of useless. It also doubles as a warning light for when the e-brake is on. That frees up a wire to be used for other things as this one simply passes through the bulkhead connector. Of course, you’d need to change the engine harness side of the bulkhead connector as well. When taping wires (vs. zip ties) to the original harness, be sure to use non-adhesive vinyl harness tape. Regular electrical tape will create a mess later as the adhesive oozes out.

I’ll also note that I joined the two amp gauge wires in the harness since the gauge would no longer be used. Check this out to see what that’s all about.

The original 4x10” speaker in the dash was garbage. I’m sure it was nothing to get excited about when it was new either. I decided to replace it with a pair of high-power 3.5” speakers (rather than install speakers in the doors or kick panels).

I started with a pair of Boss 3.5" 2-way speakers rated at 200 watts peak/100 watts RMS. Check out the little tweeter. That's a familiar looking shape isn't it? I also picked up a 4x10" to 3.5" adaptor. These items were purchased online. $20 for speakers and under $5 for the adaptor.

These mounting holes don’t line up with dash frame mounts

The plastic adaptor (intended for GM vehicles) was not a bolt-in as I had hoped. The two mounting holes at either end fall way short of the mounts in the a-body dash frame. I also found that the tweeters in the speakers extend above the mounting surface of the speakers by about 3/8". A flat adaptor plate causes the speaker to interfere with the grille in the dash frame. That means a different adaptor, spacing the speakers away from the plate, or different speakers.

So, I took the original speaker mount, blasted and repainted it. Then took the plastic adaptor and zipped the ends off with my table saw. I sandwiched the two pieces together using matching holes in both the factory mount and plastic plate.

I had to drill a couple of additional holes in the factory mount but then the speakers bolted right up to the “sandwich”. Sandwiching the two pieces got the speaker low enough to not interfere with the dash grille.

I also wanted to pre-install the stereo head (Sony GT610Ui - not too cheap or expensive) unit in order to make sure it fit before I installed the dash assembly in the car. I’m glad I did...

The pre-cut, DIN sized, opening in the Rocky Mountain Dash was too precise! The mounting bracket that came with the stereo wouldn’t fit in the opening. I had to file away about 2mm of material on one edge to make the opening big enough to accept it. RMD should have looser tolerances in this area.

With the stereo in place I reinstalled the dash harness, routing it the way it was originally. I made the connections for stereo power and front speakers, and finally turned my attention to the defrost ducts and hoses.

I really didn’t want to spend $60 or more for reproduction hoses. The ducts themselves are 2.5” in diameter. One outlet on the heater box is 2” and the other is about 2.25”. So, I ordered some 2“ and 2.5” duct hose from Nostalgic Air Parts who sells hose by the foot along with their 2” to 2.5” adaptor. I attached a piece of 2.5” directly to one of the ducts in the dash. I then attached a short piece of 2.5” hose to the other duct, followed by the reducer, and then the length of 2” hose. If you look closely at the left hose above you can see it.

The nice thing is, the 2” hose fits on the heater box outlet snugly, and the 2.5” hose fits the slightly smaller outlet with enough interference that it would probably stay on by itself. A zip tie will secure it for sure.

The dash assembly was now ready to go back in the car.

Prior to installing the dash, the wiper system, heater box, driver’s side fresh air box, and brake pedal assembly were installed.

The dash assembly then went back in without a hitch. With the glove box door cover attached to the original door, it’s easier to leave it loose on the hinge, close the door and make sure it’s aligned where you want, and then tighten the hinge screws from behind. The hinge won’t necessarily sit square in the opening. If you try to align the hinge square to the opening and frame then the door won’t open/close right or have an even, proper gap on the left. Once the door is working well then I finished installing the latch hardware and a new glove box liner.

The body harness that runs to the rear is simply plugged back into the dash harness and the bulkhead connector re-attached to the firewall. I also installed the steering column, new e-brake cable, hung the e-brake handle - all pretty simple things... re-connecting, re-bolting, re-plugging.

Everything in the dash worked great with no electrical problems. Later, I did find that the fuel gauge didn’t seem to be calibrated correctly (read 1/4 full when the tank was bone dry) so it was returned to Autometer who quickly replaced it with a unit that was calibrated right.

See the Reassembly page for final details

on the dash and other interior items.

on the dash and other interior items.

For reference, the color codes of the factory cluster plug for most a-bodies is this. A factory service manual on CD will also contain wiring diagrams:

Dark Blue w/tracer = Ign-on, +12v

Dark Blue = Fuel sender

Violet = Temp Sender

Orange = Instrument Lights

Red = High Beam Indicator

Light Green = Left Turn Signal

Tan = Right Turn Indicator

Black = Brake warning light (ground)

Gray = Oil Light (ground) ot to sender

Dark Blue = Fuel sender

Violet = Temp Sender

Orange = Instrument Lights

Red = High Beam Indicator

Light Green = Left Turn Signal

Tan = Right Turn Indicator

Black = Brake warning light (ground)

Gray = Oil Light (ground) ot to sender

The original dash pad was restored by Dashboard Restorations USA located in my home state.

|

|

|

|

|

|

|

|

|

© 2013 JP Herrick Enterprises - All Rights Reserved

Site updated: January 2014