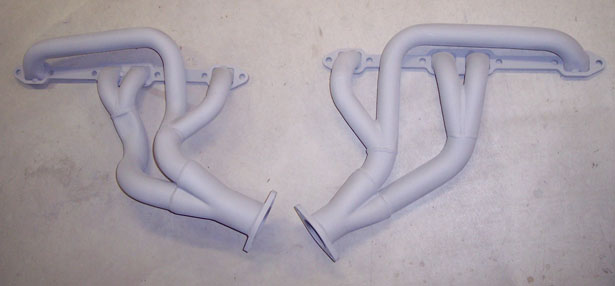

Very early in the project I decided to use Schumacher Tri-Y headers since they were engineered specifically for Big Block conversions. They’re very well made with extra thick flanges and tuck in nicely around the block without capturing the starter or hitting the power steering gear. Available in chrome of plain, I decided to go with plain because I was afraid they might discolor upon startup. TTI’s are another popular header for big block a-bodies.

I first painted them with high temp silver exhaust paint but quickly realized it probably wouldn’t hold up well. So, I’m trying a product from Techline Coatings called Colorgard “Stainless”. It’s a extreme temperature thermal coating - not a paint - that can be applied by the end user. It’s sprayed on very thinly and cures quickly. Full cure is reached when the engine is started and they heat up. Above, the headers have been coated but not yet polished.

Once installed, the above pics will give you some idea of clearance. One of the tubes (not visible) passes close to the power steering box. Overall, they fit great with lots of room where it counts.

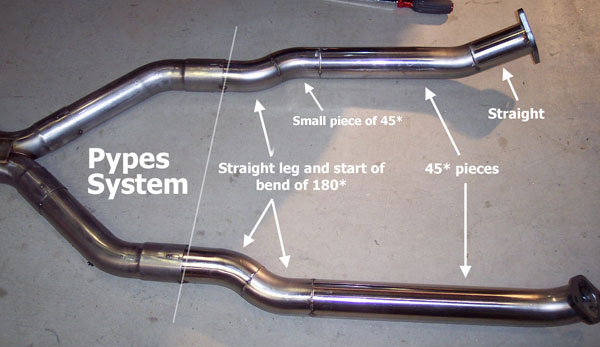

I purchased the Pype’s Performance exhaust system with their Race-Pro mufflers through Summit. It’s an all stainless system that includes the tail pipes and the hardware. Course, it’s designed for full-length headers so I had to fabricate downpipes to join the system to the Schumacher headers. I ordered two 45 degree and two 180 degree 2.5” stainless bends made by Magnaflow. They were the least expensive stainless bends available from Summit.

I spent a lot of time determining angles and cutting pieces to ensure the downpipes and the entire system stayed tucked up under the chassis. The downpipes basically come straight back from the collectors and then jog to pass through the cutouts in the trans cross member. The forward sections of the x-pipe had to be shortened (off the ends where the x is) in order to bring them closer together and meet the downpipes.

Bear in mind that the headers dump and are angled differently on each side of the engine. The cross member cutouts are also offset (remember the trans tunnel offset?) so nothing is symmetrical. Don’t cut two identical pieces of pipe and expect them to fit both sides.

I tacked the pieces together with a mig welder and then took everything down to a muffler shop to have the joints fully welded with stainless wire.

Bear in mind that the headers dump and are angled differently on each side of the engine. The cross member cutouts are also offset (remember the trans tunnel offset?) so nothing is symmetrical. Don’t cut two identical pieces of pipe and expect them to fit both sides.

I tacked the pieces together with a mig welder and then took everything down to a muffler shop to have the joints fully welded with stainless wire.

For now, I decided to not install the tail pipes. I kinda like the noise. I took some leftover pipe and cut a couple turn-down sections (not pictured) to direct the exhaust to the ground.

The Race Pro muffler features a straight through design with a simple perforated tube. The tube is wrapped in steel mesh and the case filled with a basalt material. .The case is 14" long with all stainless construction.

In Spring of 2013 we tried a pair of Violator mufflers. The difference between the Race Pro and Violator is, the Violator lacks any kind of packing inside the case. The perforations if the tube that pass through it are also larger and protrude into the exhaust stream which means the installation is directional. Definitely louder but I didn't care for the note (even installed in the "quieter" reversed direction). Sounded more like a car with bad mufflers. You can judge for yourself here.

In Spring of 2013 we tried a pair of Violator mufflers. The difference between the Race Pro and Violator is, the Violator lacks any kind of packing inside the case. The perforations if the tube that pass through it are also larger and protrude into the exhaust stream which means the installation is directional. Definitely louder but I didn't care for the note (even installed in the "quieter" reversed direction). Sounded more like a car with bad mufflers. You can judge for yourself here.

For best results set playback quality to 360p or higher

|

|

|

|

|

|

|

|

|

© 2013 JP Herrick Enterprises - All Rights Reserved

Site updated: January 2014